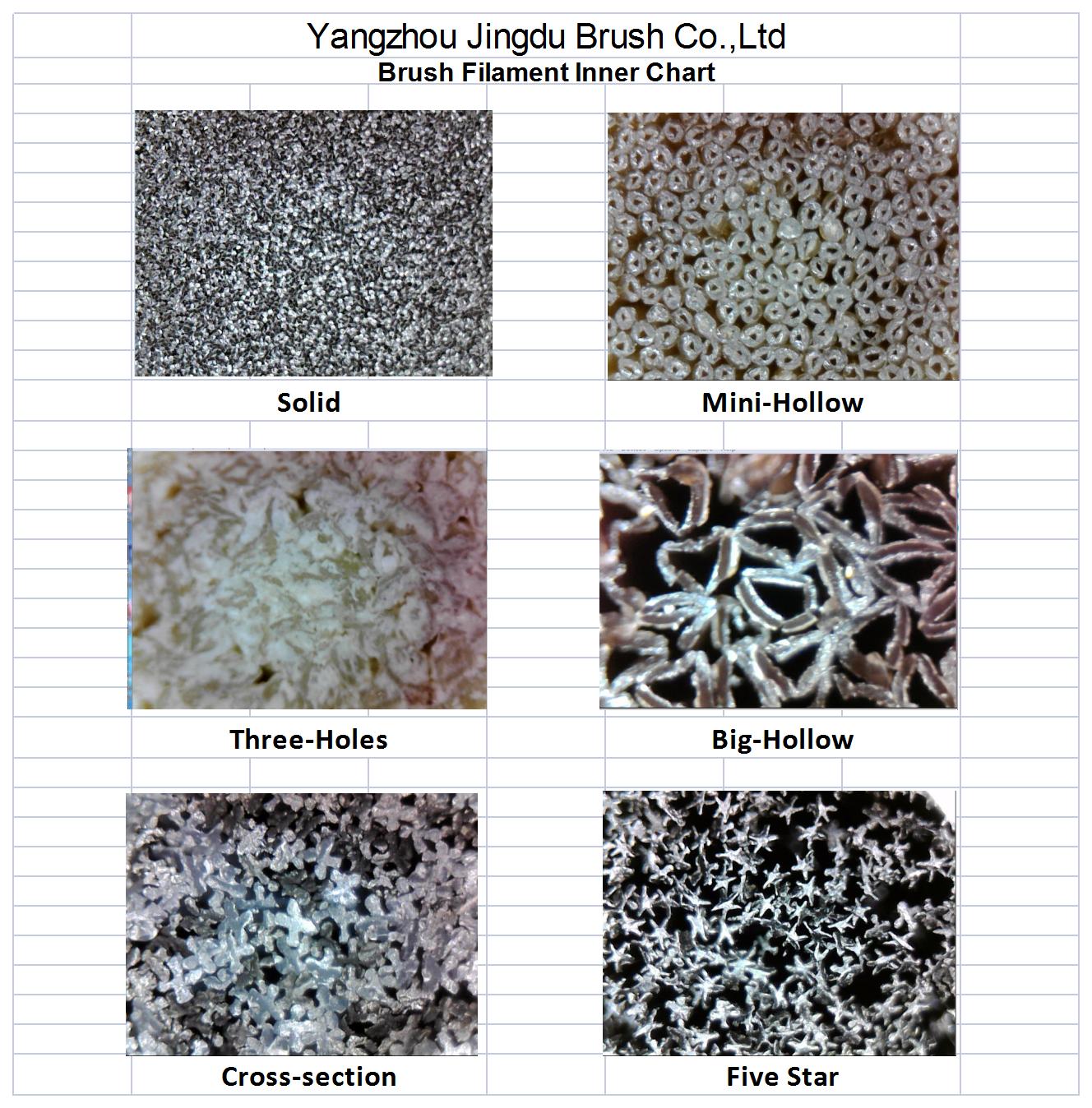

overview of the advantages and disadvantages of four different types of synthetic filament configurations: cross-section, minihollow, solid, and three holes tapered.

Overview of the advantages and disadvantages of four different types of synthetic filament configurations: cross-section, minihollow, solid, and three holes tapered.

1. Cross-Section Filament:

- Advantages:

- Enhanced Surface Area: Cross-section filaments often have irregular shapes or grooves that increase their surface area. This can improve their ability to pick up and retain liquids or particles, making them effective for cleaning tasks.

- Increased Flexibility: The irregular shape of cross-section filaments can contribute to greater flexibility, allowing brushes or brooms to conform to irregular surfaces or reach into tight spaces.

- Disadvantages:

- Potential Weak Points: The irregularities in cross-section filaments may create weak points where the filament is more prone to breakage or deformation, reducing overall durability.

- Cleaning Challenges: The complex shape of cross-section filaments can make them more challenging to clean thoroughly, potentially leading to buildup of debris or contaminants.

2. Minihollow Filament:

- Advantages:

- Lightweight: Minihollow filaments are often lighter than solid filaments, which can reduce fatigue during prolonged use, especially in handheld tools like paintbrushes or toothbrushes.

- Insulating Properties: The hollow structure of minihollow filaments can provide insulation against temperature extremes, making them suitable for applications where heat resistance or insulation is required.

- Disadvantages:

- Reduced Durability: The hollow interior of minihollow filaments may compromise their overall strength and durability, leading to potential breakage or deformation under heavy loads or pressure.

- Cleaning Concerns: The hollow structure can trap moisture or debris, posing challenges in terms of cleanliness and potential for bacterial growth if not adequately sanitized.

3. Solid Filament:

- Advantages:

- Enhanced Durability: Solid filaments typically offer greater strength and resistance to breakage compared to hollow filaments, making them suitable for demanding applications where durability is paramount.

- Easy to Clean: The solid structure of these filaments facilitates easier cleaning, as there are no hollow spaces where debris or contaminants can accumulate.

- Disadvantages:

- Potential Stiffness: Solid filaments may be stiffer compared to hollow or tapered filaments, which could limit their flexibility and adaptability to certain tasks or surfaces.

- Weight: Solid filaments tend to be heavier than hollow filaments, which may cause increased fatigue during prolonged use, particularly in handheld tools.

4. Three Holes Tapered Filament:

- Advantages:

- Improved Paint Pickup: The tapered shape of these filaments can enhance their ability to pick up and distribute paint evenly, resulting in smoother finishes and reduced brush marks.

- Reduced Brush Marks: The tapered design helps to minimize brush marks and streaks, making these filaments suitable for applications where a smooth, professional finish is desired.

- Disadvantages:

- Complexity: The manufacturing process for three holes tapered filaments may be more complex and costly compared to simpler filament configurations, potentially impacting production efficiency and cost.

- Limited Applicability: While beneficial for certain applications like painting, the tapered shape may not be as versatile for tasks requiring stiffness or abrasive action, limiting their suitability in some contexts.

Overall, the choice between these filament configurations depends on the specific requirements of the application, balancing factors such as durability, flexibility, cleaning ease, and performance characteristics.